Regardless if you are cutting the identical detail on a daily basis, or transforming materials to meet customer demands, a Move waterjet will Obtain your operate accomplished.A further thing to take into account is pace and accuracy, particularly when your purpose would be to mass produce a product to sell in just a minimal time. And You will need

How Much You Need To Expect You'll Pay For A Good precision machining

I personally acquired the 20W a single but 10W remains to be much more than sufficient for dwelling jobs. There’s now even a 40W Model You should purchase for approximately $1100 to be a standalone accent.A different factor to consider is speed and accuracy, particularly if your intention will be to mass deliver a product to market in a constrain

Facts About CNC mold milling Revealed

Cost: The Wecreat Vista is priced at approximately $799.99, which is not the most spending budget-helpful price for just a laser cutter of this measurement, and You will need to purchase extras much like the two-watt IR laser for engraving metal, the smoke purifier, and materials additionally.Yet another detail to consider is velocity and precision

The Basic Principles Of CNC punching machines

Low-sounds and minimal-emission operation along side exceptionally very simple Laptop-supported Procedure for precision at the drive of a button predestine this series to be used under the harshest running circumstances in business and trade, from one-change operation to 24/7.This is more highly effective than the Glowforge Pro’s 45W, and it’s

Fascination About CNC plasma

We have been committed to furnishing you With all the tools you must maintain your program jogging at its ideal. Experienced training is on the market in both classroom options, and on-internet site. Very best for these ProgramsYou next really need to down load Wecreat's Makeit! software, which now features a new AI graphic generator, and can exper

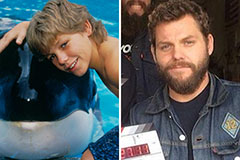

Bradley Pierce Then & Now!

Bradley Pierce Then & Now! Jason J. Richter Then & Now!

Jason J. Richter Then & Now! Romeo Miller Then & Now!

Romeo Miller Then & Now! Tatyana Ali Then & Now!

Tatyana Ali Then & Now! Anthony Michael Hall Then & Now!

Anthony Michael Hall Then & Now!